Automated Broiler Feeding: Boosting Efficiency in Broiler Production

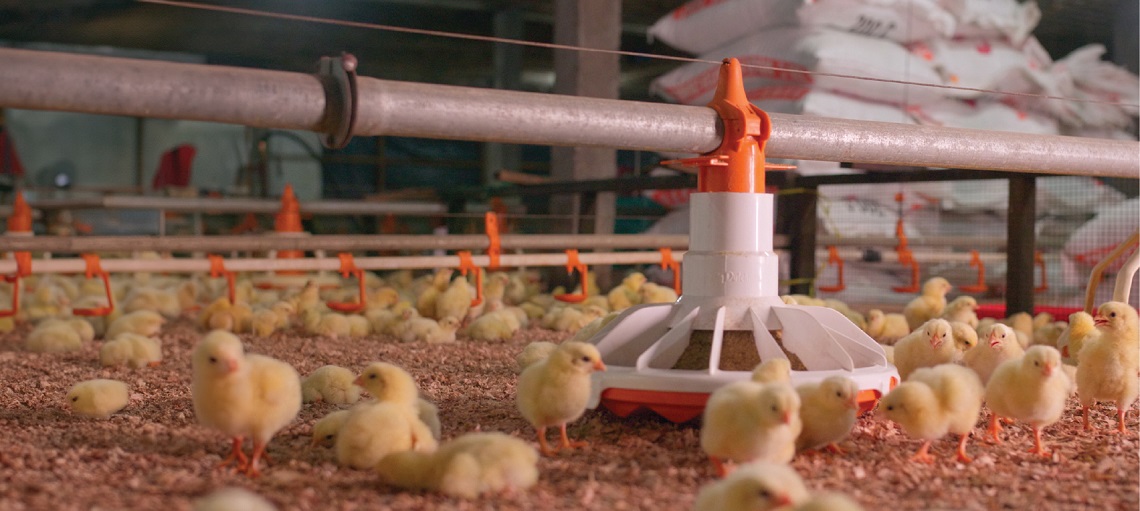

Efficient feeding with minimal wastage is one of the most critical operational aspects in the broiler production industry. Increasing demand for poultry meat and tightening profit margins means farmers are turning to automated feeding systems to enhance productivity, reduce waste, and improve overall flock management. These systems are revolutionising the way broilers are fed, from day-old chicks to maturity, offering numerous benefits for modern poultry farms.

Automated feeding systems are technologically advanced solutions designed to deliver precise amounts of feed to poultry flocks without the need for constant manual intervention. These systems use a combination of machinery, sensors, and software to streamline the feeding process, ensuring consistent nutrition and reducing feed wastage.

Benefit of Automated Feeding Systems in Broiler Production

1. Increased Efficiency

Automation reduces the time and labour required for feed distribution, allowing farm workers to focus on other critical tasks. No doubt that the automated feeding systems will still need to be supervised by humans, but it surely makes the work more efficient to be able to achieve the desired results.

2. Reduced Feed Waste

Feed waste can account for a significant portion of production costs. Automated systems deliver precise quantities of feed, minimising spillage and overfeeding. This can lead to feed savings of 5-15%, depending on the system used, contributing significantly to the bottom lines of broiler producers.

3. Consistent Flock Performance

Uniform feeding ensures that all birds in the flock have equal access to nutrition, reducing disparities in growth rates. This consistency translates to higher market weights and better overall flock performance.

4. Enhanced Biosecurity

Automation reduces human contact with feed, lowering the risk of introducing pathogens into the poultry house. This is especially important in an industry where biosecurity concerns are paramount.

5. Data-Driven Decision Making

Many automated feeding systems are equipped with smart technologies such as BFN Fusion that collect data on feed consumption, bird behaviour, and environmental conditions. Farmers can use this information to make informed decisions and optimise their operations.

Key Automated Feeding Systems for Broiler Management

Let’s explore key automated feeding systems, their advantages, and how they optimise broiler production at every stage of growth. Whether you’re a seasoned farmer or new to the industry, understanding the potential of these systems can help you make informed decisions to boost efficiency and profitability.

1. Pan Feeding Systems

Pan feeders are widely used in broiler production due to their reliability and flexibility. These systems consist of interconnected feeding pans that deliver feed directly to the birds at floor level, making them accessible for broilers at all stages of growth.

Benefits of Pan Feeding Systems:

- Ease of Access: Pans are adjustable to different heights, accommodating broilers as they grow

- Uniform Feed Distribution: Ensures that all birds, including weaker ones, have equal access to feed

- Reduced Labor: Automation eliminates the need for manual feed distribution

For even more precise feeding, farmers can opt for Big Dutchman’s Vista 330 feed pan that is designed for optimal broiler feeding. It features consistent and controlled feeding with the innovative 360o flooding mechanism with an automatic shut off function and a grill-less design.

2. Chain Feeding Systems

Chain feeders are another popular option for broiler and breeder farms, These systems use a conveyor-like mechanism to distribute feed evenly along a feeding trough. They are particularly suitable for large-scale operations where consistency is crucial.

Advantages of Chain Feeders:

- High Efficiency: Capable of delivering feed to thousands of birds within minutes

- Customizable Settings: Feed delivery rates can be adjusted based on flock size and growth stage

- Durable Design: Built to withstand long-term use in demanding conditions

Big Dutchman of course is a pioneer in chain feeding by introducing the world’s first automatic chain feeding system back in 1938. In fact, the basic concept of the system is still retained to this very day, along with improvements that ensures a robust and cost-efficient feeding system with a long service life.

3. Auger Feeding Systems

Auger systems rely on spiral conveyors to transport feed from storage silos to feeding stations. These systems are particularly effective for delivering specific feed quantities to multiple locations within a poultry house.

Key Features of Auger Feeders:

- Automated Portioning: Ensures precise feed allocation for optimal growth

- Scalable Design: Suitable for farms of all sizes, from small operations to industrial-scale facilities

- Minimal Human Intervention: Reduces the risk of contamination and human error

As an improvement to traditional auger systems, FlexVey PUR from Big Dutchman is an innovative conveying mechanism that is highly resistant to wear and tear, while ensuring the feed that reaches the house is safe and intact.

4. Feeding Silos with Automated Distribution

Feeding silos, paired with automated distribution systems, are a staple of modern broiler farms. These systems store large quantities of feed and deliver it to feeders as needed, reducing the frequency of refilling.

Advantages of Silo Systems:

- Bulk Storage: Reduces the need for frequent feed deliveries, saving time and transportation costs.

- Precision Feeding: Works seamlessly with automated feeders to maintain consistent rations.

- Enhanced Biosecurity: Minimises human contact with feed, lowering the risk of contamination.

Many modern, multi-house broiler producers in Asia have opted for Big Dutchman’s centralised feed storage and feeding system that help to minimise biosecurity risk and efficiently distribute feed throughout the farm. This system is also built-in with weighing and monitoring systems to help ensure farmers will never run out of feed.

Automated feeding systems are transforming broiler production by providing farmers with efficient, precise, and sustainable solutions to manage their flocks. From pan feeders to advanced silo systems, these technologies ensure that broilers receive consistent nutrition at every stage of growth, boosting productivity and reducing costs.

As the demand for poultry meat continues to rise, investing in automated feeding systems is not just a smart business decision—it’s a necessity for staying ahead in a competitive market. By leveraging these technologies, farmers can achieve better flock performance, enhance biosecurity, and contribute to a more sustainable future for poultry farming.

Learn more about Big Dutchman’s automated feeding systems. Click the ‘Send a Message’ Button below to talk to us.