Broiler Performance: 8 Key Factors for Optimal and Healthy Growth

From the moment day-old chicks are placed to the point they reach the target weight, there are various factors that influence their performance. Every commercial broiler producer knows that taking control of these factors is pivotal to ensure the flock can attain its full growth potential.

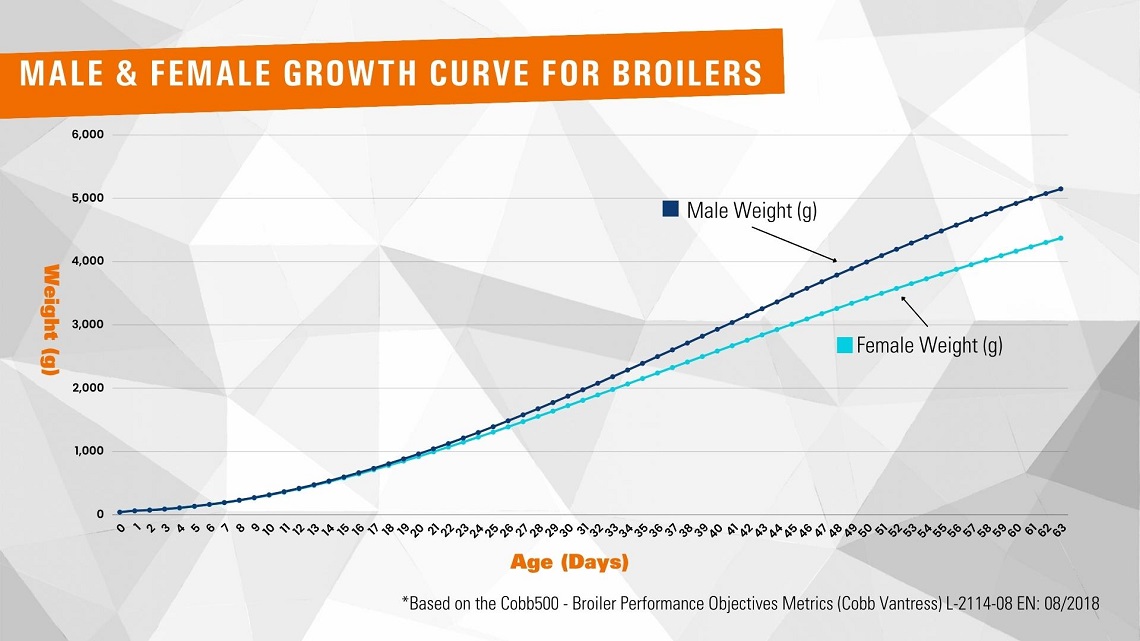

Monitoring and managing all critical factors throughout every developmental phase is essential to achieve the optimal broiler growth curve as pictured above. Let’s take a look at the 8 key factors that will determine the success of your broiler production, ultimately delivering the highest returns for each cycle:

1. Feed & Nutrition

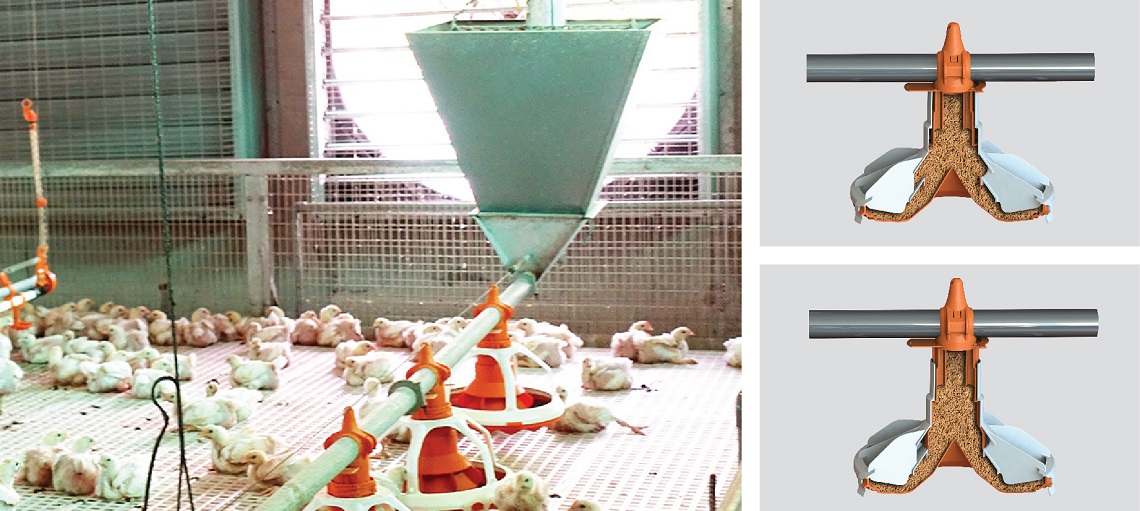

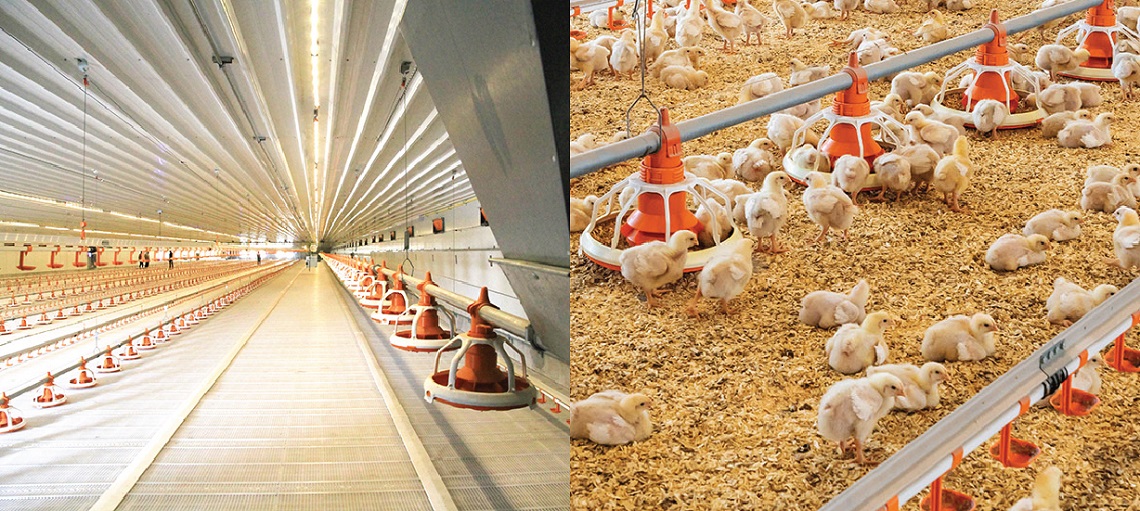

As the costliest element of broiler production, proper nutrition is also paramount for growth and health. Formulating well-balanced diets with the right mix of protein, energy, vitamins, and minerals is crucial. Nutrition also includes feed quality, availability, and distribution using proven equipment such as augers and feed pans. A well-managed feeding programme by paying special attention to Feed Conversion Ratio (FCR) is essential to achieve the best performance in each production cycle.

2. Water Quality & Availability

Clean, high-quality water is as important as feed. Water aids digestion, promotes nutrient absorption and provides proper hydration to keep the birds healthy and active. Adequate water supply and easy access are vital for broiler health and performance.

3. Environmental Conditions

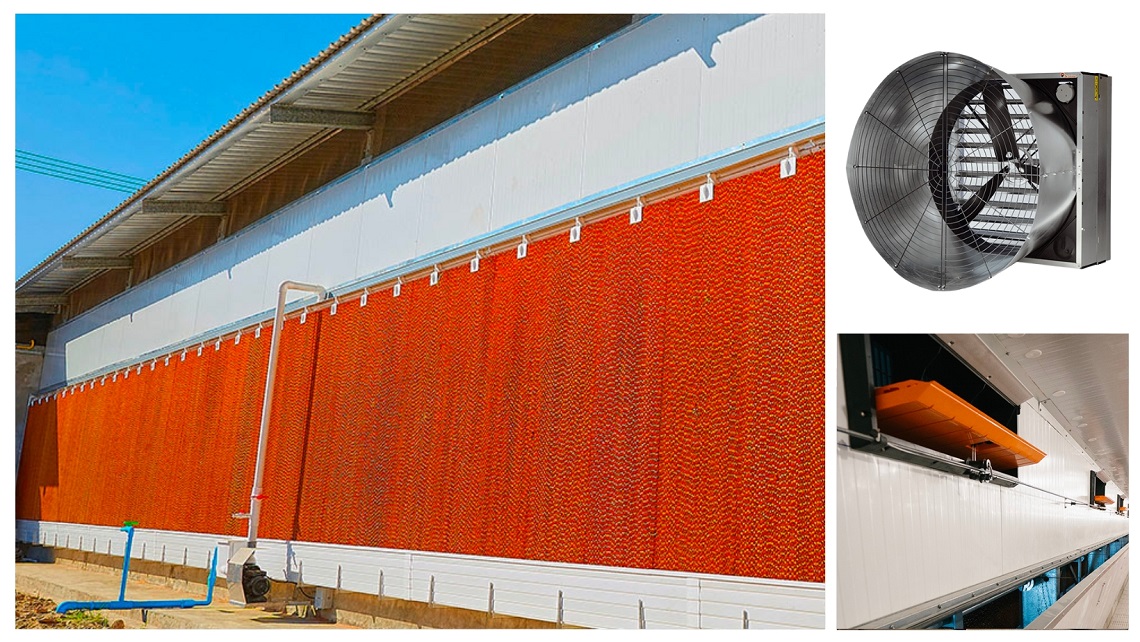

One of the most important non-dietary factors influencing feed conversion is the microclimate within the broiler house.

- Temperature: Broilers are sensitive to temperature. Maintaining appropriate temperature levels through correct ventilation, heating and cooling are crucial to prevent heat stress that can lead to poor growth and mortality. Furthermore, optimal temperatures allow broilers to convert nutrients into growth rather than for their internal temperature regulation, hence maintaining feed conversion efficiency.

- Humidity: Maintaining optimal humidity levels helps prevent heat stress and reduces the risk of respiratory issues. Using a climate controller that provides different functions to deal with humidity is key in preventing dusty or wet litter, and high levels of ammonia.

-

Lighting: The duration and intensity of light can impact broiler behaviour, feeding patterns and growth. Proper lighting equipment and programmes following the growth phase of broilers are essential in promoting flock wellbeing.

- Air Quality: Good air quality is vital to prevent respiratory problems. Using sensors to measure temperature, humidity, CO2 and ammonia is necessary to create a comfortable living environment.

4. Disease Prevention

Disease prevention and control are crucial for broiler performance. Vaccination, biosecurity measures, and regular health monitoring are essential components of disease management. The entire feeding, watering and house condition must be kept free of pathogens and pests to promote wellbeing throughout the production cycle.

5. Litter Management

Litter is defined as the combination of bedding materials, excrement, feathers, wasted feed and wasted water. Hence it is significantly important to maintain a clean and dry litter for broilers, preventing health conditions such as footpad dermatitis and breast blisters, while minimising ammonia emissions.

6. Stocking Density

Overcrowding can lead to stress and poor performance. Maintaining an appropriate stocking density is essential to prevent feed competition and negative flock behaviour. Factors to consider when determining stocking density include bird size, feeder spacing, drinker spacing, house dimensions and bird breed among others.

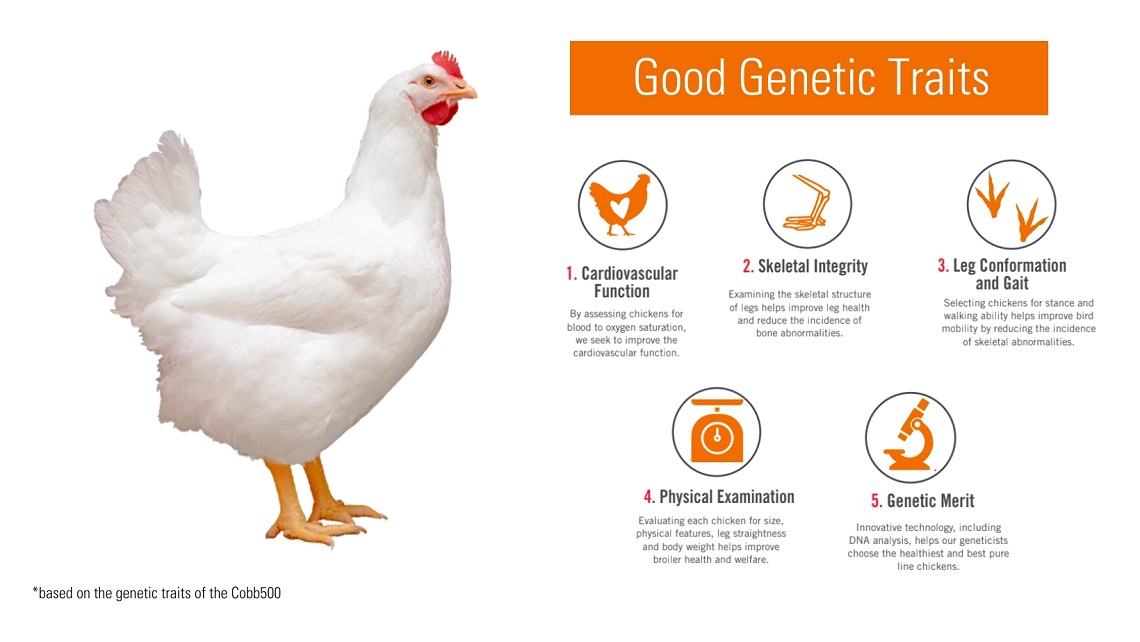

7. Genetics

The genetic selection of broiler breeds plays a fundamental role in determining growth rates, feed efficiency, and overall performance. Some breeds grow naturally faster compared to others, while each breed will require its own specific management style for optimal growth. Choosing breeds that are well-suited to your production and business goals is essential.

8. Human Element

The personnel working in broiler houses also play an important role in helping ensure optimal growth and performance. Maintaining strict levels of hygiene and adhering to biosecurity minimises the risk of cross-contamination that can jeopardise the health of an entire flock. Moreover, any human interaction with the birds, especially when they are young, need to be done carefully and deliberately to avoid stress.

The success of growing broilers lies not only in optimising individual components but also in the synergy of these elements. A well-informed and adaptable approach to broiler management, coupled with a dedication to bird health and welfare, is essential for consistently achieving the desired growth rates, feed efficiency, and overall performance.

As one of the pioneers of modern broiler production equipment and systems in Asia since 1992, Big Dutchman has partnered with thousands of broiler producers to enhance and grow their poultry business. You will find the Big Dutchman expertise and technology behind some of the most modern and largest broiler production facilities in the Asia Pacific region, a testament to our continued innovation and service centric philosophy.

Have you covered all the bases in your broiler production farm? Let us help. Click the ‘Send a Message’ Button below to talk to us!