FCR Essentials: Understanding and Optimising Feed Conversion Ratio in Poultry Production

As the cost of feed continues to rise, quantifying how effectively birds convert feed into body weight is a critical measure of the profitability of a poultry production operation. A low FCR is desirable as it means that less feed is required to produce a kilogram of poultry product, which translates to lower feed costs and higher efficiency.

Optimising FCR is not only economically beneficial for poultry producers but also has environmental implications. By reducing the amount of feed needed to produce poultry products, farmers can lower their production costs and minimise the environmental impact such as waste production, ensuring a more sustainable operation.

The relationship between feed intake and the amount of meat a bird produces is an inverse coefficient that can be calculated by dividing the amount of food eaten with the weight of one chicken. For example, if a bird ate 3.8 kgs of feed and ends up with a live weight of 2 kgs at the end of the production cycle, the FCR is 1.9. Whereas if another bird ate 4 kgs and ends up with a live weight of 2.5 kgs, the FCR is 1.6, which is a much better conversion ratio.

FCR is Reliant on More than Just Feed

While the amount of feed is the core contributing factor influencing FCR, there are other elements that also play a determining role.

1. Genetics

Genetic selection plays a significant role in determining the growth rate, feed intake, and feed conversion efficiency of poultry breeds. Selecting breeds with favourable genetic traits for efficient growth and feed utilisation can contribute to lower FCR.

2. Nutrition

Proper nutrition is crucial for optimizing FCR. Balancing diets with the right mix of protein, energy, vitamins, and minerals ensures that birds meet their nutritional requirements for growth without excess feed wastage.

3. Feed Quality

The quality of feed ingredients, including their digestibility, nutrient content, and freshness, directly impacts FCR. High-quality feeds result in better feed utilisation and lower FCR.

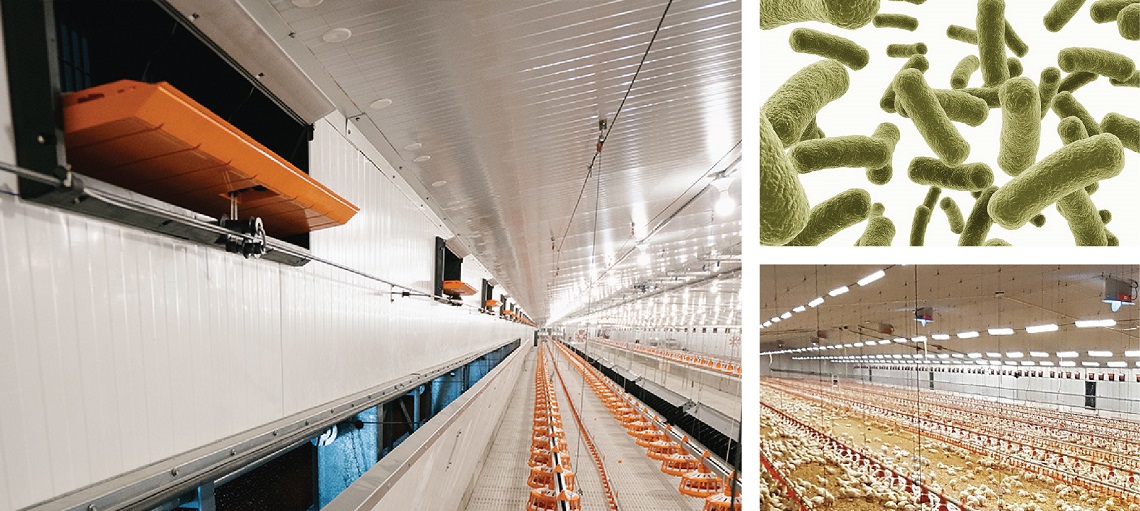

4. Health and Disease

Healthy birds with optimal immune function are more efficient at utilising feed. Disease outbreaks or health issues can negatively impact FCR by reducing appetite, nutrient absorption, and overall growth rates.

5. Environmental Conditions

Factors such as temperature, humidity, ventilation, and stocking density can affect bird comfort, stress levels, and feed intake. Providing a conducive environment promotes better FCR.

6. Management Practices

Effective management practices, including proper housing, sanitation, water quality, and feeding programs, are critical for optimising FCR. Overcrowding, feed wastage, and inconsistent feeding schedules can lead to higher FCR.

Strategies for Optimising FCR

The advent of precision farming technology and robust management practises, poultry producers can achieve optimum FCR to keep feed costs at an acceptable level.

1. Precision Feeding and Environmental Monitoring

Precision feeding technology, which uses data and sensors to tailor feed rations to the specific needs of the birds, can significantly enhance FCR. IoT devices and sensors monitor environmental factors such as temperature and humidity, which are crucial for maintaining optimal conditions for poultry growth. Automated feeders and robotic systems help regulate feed distribution, reduce waste, and perform tasks like egg collection and health monitoring, further optimizing FCR.

2. Nutritional Enhancements

The inclusion of enzymes in poultry diets is a nutritional strategy that can lead to a lower FCR by improving the digestibility and absorption of nutrients from feed. High-quality feed ingredients that are free from contaminants and have high nutrient digestibility are essential for achieving an efficient FCR. Tailoring feed formulations by balancing between energy and amino acids to meet the nutritional requirements of chickens at different life stages can also lower FCR.

3. Management Practices

Good flock management practices, such as maintaining proper lighting and temperature, regular cleaning and disinfection, disease control, and vaccination, are vital for optimizing FCR. Pelleting feed has been shown to improve feed conversion by increasing body weight, reducing feed wastage, and enhancing nutrient availability. Additionally, lighting programs can influence broiler performance and welfare, potentially improving FCR.

4. Technology & Automation

The integration of technology and automation in poultry farming has the potential to significantly boost FCR and overall efficiency. Digital technologies enable real-time monitoring of individual bird weights, feed and water consumption, stress levels, and air quality, which are all important for managing FCR. The use of big data, robotics, artificial intelligence, and nanotechnology are modern innovations that can drive improvements in poultry farming efficiency.

Optimising FCR is a multifaceted challenge that involves genetic selection, nutritional strategies, technological advancements, and effective management practices. Of course, different farms with varying levels of resources will require an approach that is consistent with their production goals. Nevertheless, by incorporating at least one or two of these strategies means poultry producers of all types can enhance their operations' efficiency, reduce costs, and contribute to a more profitable production.

Looking to enhance your FCR and improve broiler performance with a suite of proven equipment and systems? Click the ‘Send a Message’ Button below to talk to us!